We are a one-stop shop capable of producing complete machined and sheet metal honeycomb assemblies with minimum outside vendor sourcing.

NADCAP-ACCREDITED PROCESSES

We maintain multiple certification standards. Our accredited processes include:

- Nadcap Heat Treating

- Nadcap Nonconventional Machining -Laser & EDM

- Nadcap Welding

- Nadcap Nondestructive Testing – FPI

ASSEMBLY OPERATIONS

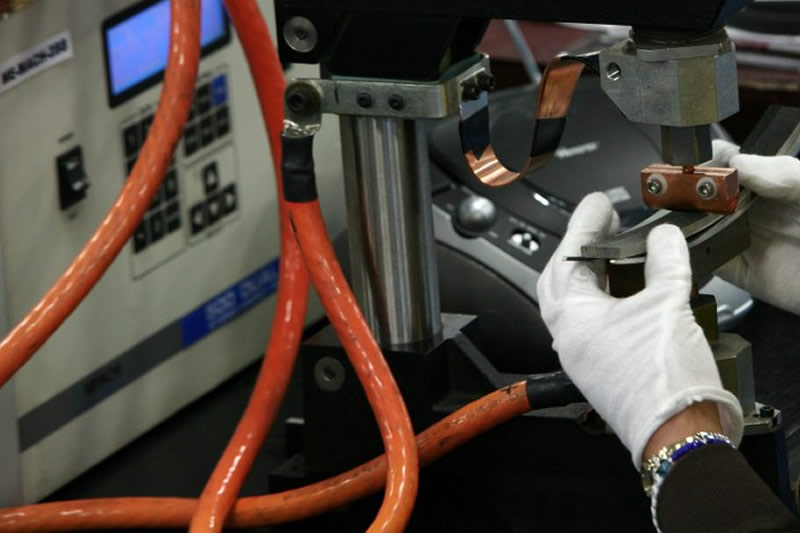

Our assembly operations include resistance welding to facilitate braze for sheet metal assemblies and fusion welding of rings and components.

BRAZE ALLOY APPLICATION

In-house application of braze alloy powder, paste, foil, and tape to assist in the brazing process.

ELECTRICAL DISCHARGE MACHINING (EDM)

Our EDM operations include wire, sinker, and In-house graphite electrode manufacturing.

EDM WIRE

We specialize in the machining of small burr-free components that include stop blocks and stop pins that are included in our assemblies. Wire EDM provides accurate and burr-free machining of length of machined segments and brazed sheet metal assemblies.

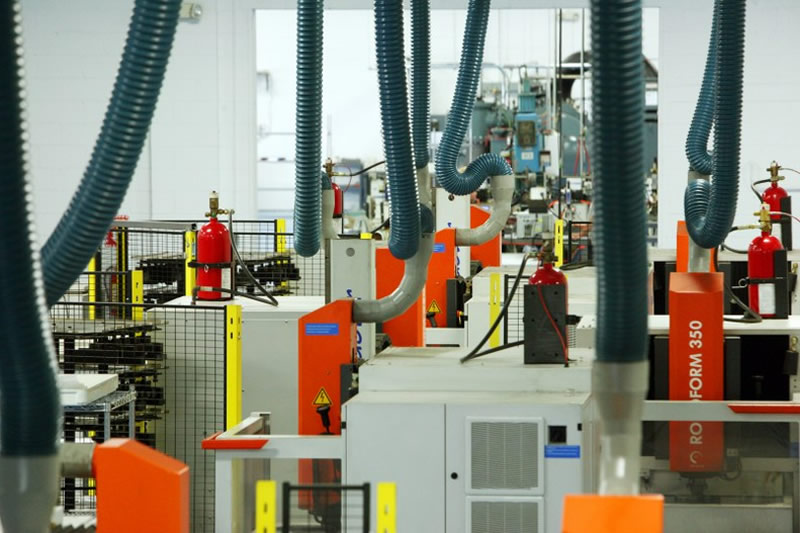

EDM SINKER

Our automated robotic EDM sinker cells allow for lights-out machining with minimal operator involvement. Features include finished length, seal slots, pockets, notches, I.D and O.D. diameter grinding.

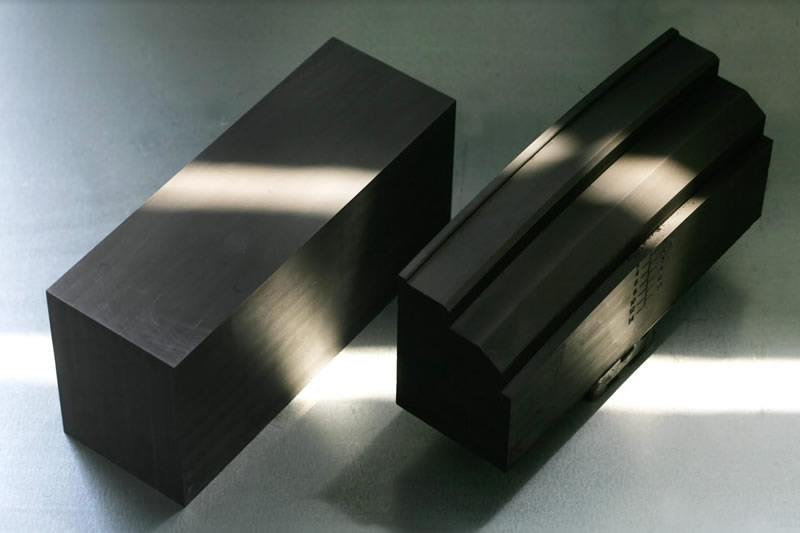

ELECTRODE MANUFACTURING

Our in-house design and graphite machining capabilities allow for the most complex shapes to be machined using our sinker EDM equipment to manufacture components and assemblies.

INSPECTION

Our capabilities include manual inspection, visual inspection, CMM inspection, in-machine probing, material analyzers, and hardness testing.

LASER CUTTING AND DRILLING

3-axis and 5-axis cutting and drilling of holes, vane slots, notches, ends, and parting capabilities.

LASER MACHINING AND DRILLING (FIBER)

Our Fiber operations include drilling, cutting, and laser engraving.

LASER ENGRAVING

Permanent, high contrast, and fast laser marking and engraving of aluminum and high nickel stainless steels.

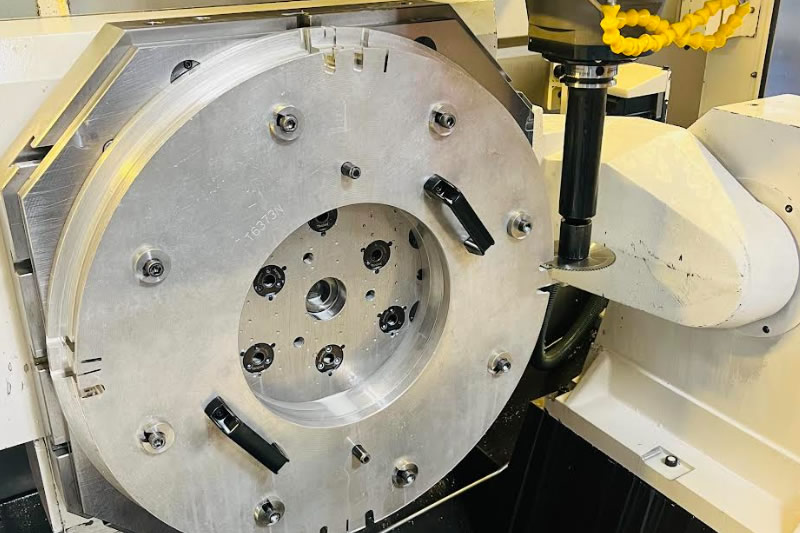

MILLING 3-AXIS, 4-AXIS & 5-AXIS

Our 5-axis milling work centers include pallet loaders to optimize efficiency and increase throughput. Every Mill in our facility includes quick change mounting systems for ease of set-up and machine changeover. Milling capabilities include machining of thermal flame spray.

PROGRESSIVE ROLLFORM MACHINING AND SHEET METAL FABRICATION

Our continuous process converts sheet metal into engineered shapes from a continuous coil to form complex cross-sectional-shaped sheet metal components.

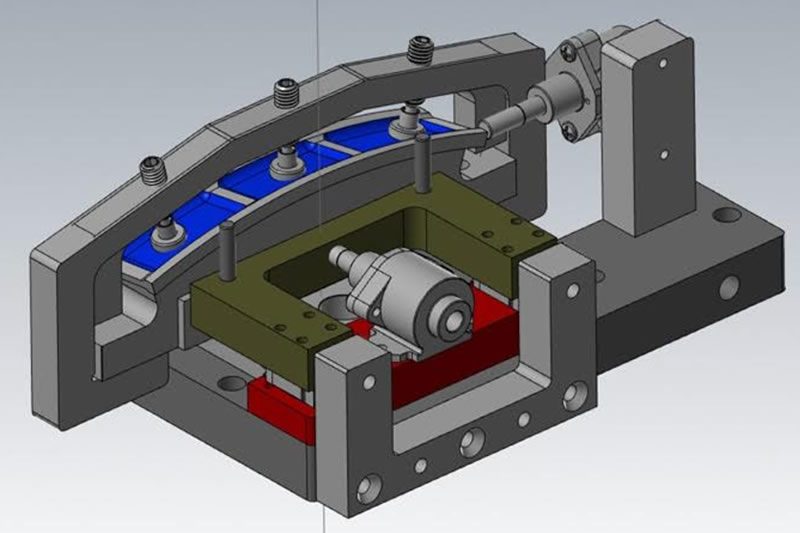

TOOL DESIGN & BUILD

In-house tool design and build capabilities allow for the quickest turnaround and shortest lead time to assist in our standard manufacturing processes.

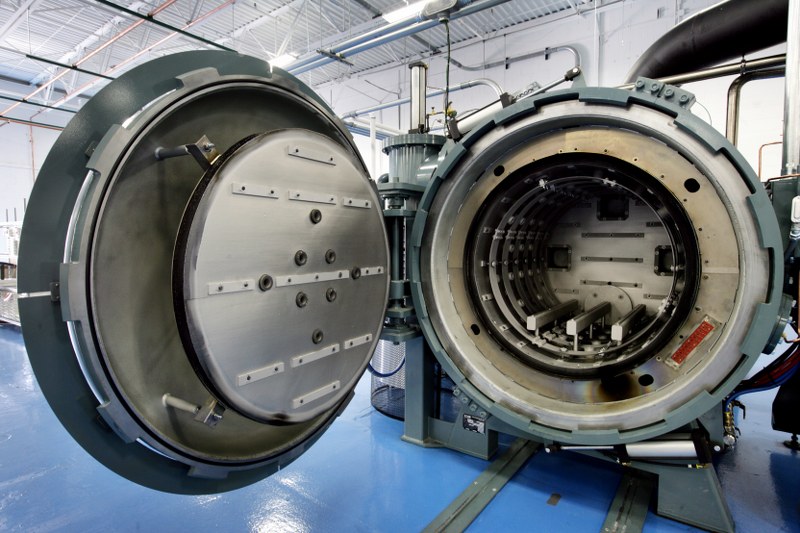

VACUUM BRAZING AND HEAT TREATMENT

Our four large vacuum furnaces are cable of brazing, stress relief operations, and aging.

WATERJET

We have two large water jets for production use to manufacture sheet metal components as well as to assist in tooling manufacture.